In search of energy, humanity has stretched the bounds of invention and discovery. Deep offshore technology is transforming techniques at deep-water and ultra-deep-water locations, therefore changing the game in terms of energy production. Examining the history, contemporary systems, issues, and possible future advances of deep offshore technology can help energy professionals, environmental engineers, and tech enthusiasts alike.

What Is Deep Offshore Technology?

Deep offshore technology is the use of advanced engineering methods and systems to discover, harvest, and manage natural resources found far under the ocean bottom. Typically, this refers to water depths exceeding 500 meters, with ultra-deep-water activities extending up to 1,500 meters.

This forward-looking industry is defined by subsea engineering, sophisticated robots, drilling advancements, and all-encompassing systems that maintain operations in hostile underwater settings. This industry is crucial in fields such as environmental management, renewable energy, and oil and gas extraction.

The Historical Evolution of Deep Offshore Technology

While attempts to find offshore resources have existed since the 19th century, actual progress was achieved in the middle of the 20th century when the petroleum business started drilling first wells in Louisiana.

The company expanded into deep-water areas in the 1970s when floating production and subsea drilling became standard.

In the 2000s, innovations included dynamically positioned systems, remotely operated vehicles (ROVs), and subsea robotic technology enabled operations in ultra-deep-water conditions.

Time-honored extraction techniques are merging modern artificial intelligence (AI), robotics, environmentally friendly engineering solutions.

The Current State and Future Trends in Deep Offshore Technology

Sustainable, efficient, and creative deep offshore technology is developing to fulfill the growing need for energy throughout the world.

Current State

- Currently, deep-water operations are being optimized via the use of automation to increase operating efficiency.

- Underwater robots and remotely operated vehicles (ROVs) carry out repair jobs with little or no human oversight.

- Modern drilling equipment precisely reaches deep reserves.

- Offshore system digital twins improve output via predictive maintenance by modeling real-time processes.

Future Trends

Artificial intelligence (AI) makes it possible to analyze vast amounts of data, therefore enhancing resource estimates and eliminating operational guesswork.

- Beyond oil and gas, deep offshore platforms are increasing their capacity for producing renewable energy, including offshore wind farms.

- Innovations with an Environmental Focus: Two technologies that are front and foremost as means to minimize the environmental impact of offshore activities are carbon capture systems and low-emission rigs.

- Modular Systems: We are developing subsea networks and modular rigs to provide quicker deployment and better flexibility.

Key Components and Infrastructure of Deep Offshore Systems

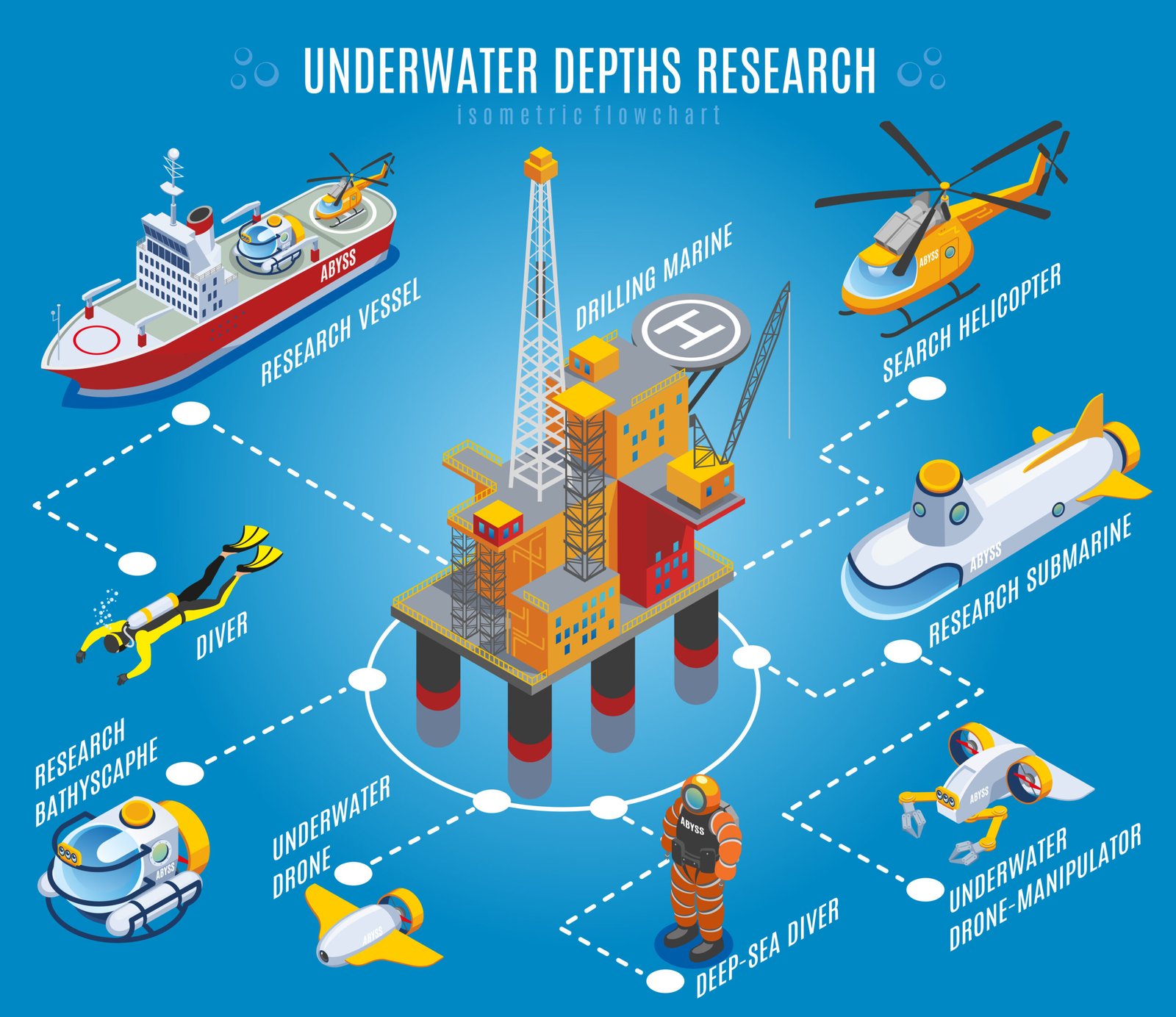

Complex systems and infrastructure are essential to deep offshore technology, which includes:

Offloading and Storage Units for Production on the Water (FPSOs):These boats combine production and storage capacities to support distant offshore activities.

Systems for Subsea Production: These include Christmas trees, manifolds, and control systems that enable processing and extraction to take place underwater.

Dynamic positioning systems: Platforms and boats can stay put in any storm thanks to advanced navigation technologies.

Underwater robotics: Underwater robotics is the use of autonomous underwater vehicles ( AUVs) and robotic underwater vehicles ( ROVs) to do chores such pipeline inspection and equipment repair.

Environmental and Safety Considerations in Deep Offshore Operations

Deep offshore operations are associated with specific environmental and safety concerns.

Thinking about the environment:

Ecosystems in the Ocean:

- Drilling and producing operations may disturb habitats in the ocean. To lessen these impacts, there have been innovations in quieter equipment and less invasive processes.

- Modern blowout preventers (BOPs) and spill containment systems significantly reduce the likelihood of leakage.

- Due to the dangerous nature of the work and the isolated offshore sites, worker safety is of the utmost importance. Real-time data analytics spot possible dangers before they become major, and AI-based monitoring and automated procedures are lowering risks.

Challenges and Innovations in Deep Offshore Technology

Challenges:

Problematic Operating Conditions: High pressure, corrosive seawater, and very high temperatures all contribute to an unpleasant working environment.

Technical Limitations: Working at depths beyond 1,500 meters imposes limitations on the connection and durability of equipment.

Expensive: Large financial expenditures are necessary to construct robust infrastructure and ensure operational continuity.

Innovations:

Wear-Resistant Materials: The development of improved composites and coatings extends the lifetime of offshore equipment.

Digital twins: which are digital representations of individual rigs, simplify preventative maintenance of underwater systems.

Modern Drilling Fluids: These fluids are better for the environment and increase drilling stability.

Economic Impact and Role in Energy Production

Deep offshore technology is essential to meet the world’s energy needs.

- Offshore locations account for over thirty percent of the global oil output, which fuels generation of electricity.

- Investments in offshore projects contribute to economic growth by creating jobs in engineering, supply chain management, and research and development.

- Importance in Global Politics: Offshore resources help to diversify energy portfolios, which in turn decreases dependence on foreign suppliers and increases energy independence.

Case Studies of Successful Deep Offshore Projects

1. The Thunder Horse Field, Florida Gulf Coast

Despite difficulties in deep water, the biggest FPSO platform in the world improved extraction efficiency.

2. The North Sea’s Johan Sverdrup Field

A sustainable development strategy included a low-emission design that ran on renewable energy.

3. A gas field at Ormen Lange in the Norwegian Sea

This project’s integrated subsea production technologies enable Europe to meet its energy demands with minimum environmental effect.

How Deep Offshore Technology Fits into the Global Energy Landscape

By connecting the gap between the scalability of renewable energy and the conventional dependence on fossil fuels, deep offshore technology plays an essential role in the world’s energy problem. Hybrid rigs and offshore wind farms demonstrate this sudden change.

Conclusion and Future Outlook for Deep Offshore Technology

Deep offshore technologies represent a new and exciting area in energy generation. By incorporating cutting-edge AI systems, robots, and environmentally sensitive efforts, the industry stands poised to transform into a versatile player in the global energy market.